Traditional Floor Laying

Description and technical features

Maxfine requires the adhesive to be applied both on the setting bed and on the back of the slab. Maxfine slabs for flooring require the following conditions:- A flat surface;

- Clean and free from dust, scraps and any lumps of cement;

- The setting bed must be uniform and have already undergone the drying shrinkage process;

- Repair of any cracks;

- Any uneven parts on the surface must be filled with suitable levelling compounds.

Instruments required:

- Cement-based powder adhesive for full spread, class “C2E according to EN12004 and S1 according to EN12002 standards”;

- 3x3 mm square toothed trowel and 15 mm round toothed trowel;

- Frame with suction cups for handling or double suction cups;

- Non-bounce plastic mallet 170x370 mm;

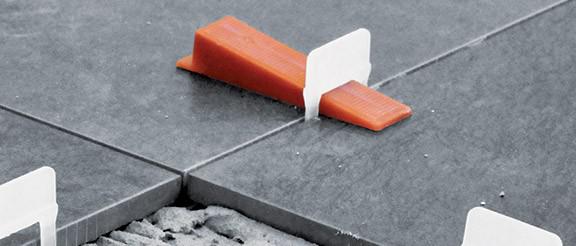

- Levelling system: base clip + wedge + pliers.

Wall Covering

Laying System

The laying system with hidden mechanical safety hook on 6 mm Maxfine slabs allows the wall covering to be installed in complete safety with a great impact.

Instruments required:

- Cement-based powder adhesive for full spread, class “C2E according to EN12004 and S1 according to EN12002 standards”;

- 3x3 mm square toothed trowel and 15 mm round toothed trowel;

- Frame with suction cups for handling or double suction cups;

- Non-bounce plastic mallet 170x370 mm;

- Levelling system: base clip + wedge + pliers.